As I’ve been showing off the 3d-printed Hart gondolas, one of the common questions I’ve gotten is “how long does it take to make the design? Could you just scan some commercial model?”

That question goes a lot to the challenge of 3d printing. Although the technology seems magical (“press a button and a freight car comes out”), there’s a huge amount of work to design a model. Having an existing thing - whether a real car or an existing model - doesn’t help. You’d need to get a scan, clean up any imperfections, add detail in the places that didn’t scan well, adjust the design to either exaggerate detail that would get lost when printing at your scale, and hide detail that won't print well.

For example, rivets smaller than about 1.5" diameter don't print well, so I usually do both rivets and bolt heads as 1.5" diameter, 1" tall cylinders. Models with a board floor need gaps drawn in to show off the boards, or require each board to be at a different height to be visible; either choice affects spacing, and how the floor attaches to other parts of the model. Detail that needs to be painted on, such as a metal strap, might need to be raised up so it can be hit with a paint brush. Metal structural parts, such as angle iron, needs to be thickened - 1/4" plate used for stiffening a railroad car would be 3/1000 inch thick - perfectly solid on the prototype, but impossibly flimsy on a model. Changed dimensions might snowball into affecting other parts of the design. Making decisions about how the design should be tweaked requires judgements about what can print reliably, and what detail is essential or unimportant for a model. For lack of a better term, it requires a bit of "art". (Folks making plastic kits have to worry about all these details all the time; check out a plastic boxcar to see the mold maker's choices.)

Fixing an existing scanned design to fix details and make the judgement calls about scale is a ton of work. In many cases, it might be easier to start with a rough idea of what you want to build, and then design from scratch in 3d, just as if you were making technical drawings on paper.

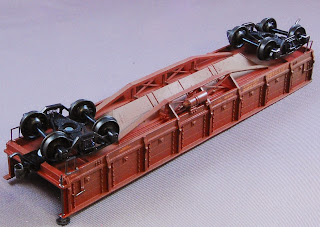

Making a 3d model of a freight car isn’t easy, either. For the three cars I’ve built (the CS-35a flat car, the F-50-4 flat car, and the Hart gondola), I built the models mostly based on photos. I grabbed my copy of Tony Thompson’s “Southern Pacific Freight Cars” book off the shelf, started with any drawings he included, then started guesstimating from the photos. For the CS-35a and F-50-4, Tony included very tiny copies of the original drawings; with these and a good magnifying glass, I could get a decent idea about measurements. With the photos in the book, I could identify some of the details, such as the shape of the stake pockets or guess at dimensions I couldn’t read.

End elevation from Hart gondola plan.

Making the 3d Model from Photos:

With the Hart gondola, I had more of a struggle; the Freight Cars book didn’t have any drawings. Tony did include minimal information on car length from an old car description, but other than that, I was on my own. Multiple times, I printed a model, then looked at the photo to compare scale and look for details I missed. The result was pretty good - certainly good enough for my model railroad - but I knew there were mistakes.

So fast forward a couple months, and I’ve decided to try doing another 3d model - this time the Southern Pacific’s “battleship” side dump ballast cars, built in 1902. These cars were critical for the early SP, helping to create the fill across the Great Salt Lake, hauling away the debris from the 1906 San Francisco earthquake and fire, and plugging the Colorado breach to stop the flooding of the Salton Sea. These were huge boxy, coarse steel freight cars that, in every photo, were dumping immeasurable amounts of rock to stop a river or cover a hillside.

For the Battleships, the book only had eight photos, mostly side views. With those, I could get the rough outward appearance. However, the insides weren't visible in any of the photos. I needed to understand how the inside of the hopper was shaped - these had a triangular shapes interior to slide rock to the outside, and those insides would be very visible on the completed model. The photos also hinted that the car was mostly hollow, with support structures underneath holding up that hopper bay. 3d printing promised to get that internal structure just right, so I really wanted to get that non-visible structure correct.

It was time to go to extraordinary lengths.

So last week, I headed up to Sacramento and the California State Railroad Museum to search for more information. The CSRM managed to save many of the plans and blueprints from the Southern Pacific, so for details on obscure, century-old railroad cars, it’s the best hope for information.

Finding the Original Hart Plans:

I went up looking for three bits of information. First, when I’d shown off the Hart cars to Tony Thompson last month, he hinted that the cars had been rebuilt in the late ‘teens. “After the rebuild, the cars were two boards higher.” I wanted to find plans for the rebuild so I could make an accurate modern version of the cars. Second, I wanted to find blueprints for the Battleship cars; although I’d been able to print a rough model, I couldn’t see how the frame of the car was built, and wanted to get that right. Finally, I wanted to poke around for more information on San Jose and the canneries.

I wasn’t so lucky with the Battleships and the rebuilt cars; plans for both are stored off-site, and need a week’s notice. (Pro tip: WS and McC call numbers on plans imply they're stored off-site in West Sacramento and McClelland Air Force Base.) However, the staff did find a beautiful set of plans for the original Hart gondolas (last revision, 1918), all on a 30x60 piece of vellum. The drawing is a beauty - some draftsman spent a huge amount of time getting the it perfect, even sketching in the wood grain on some of the posts.

And now I’d put myself in an awkward situation. I already had spent a lot of time on that original model. I’d guess I’ve spent 40-50 hours on it, both in getting the rough design done, and fine-tuning it for printing. And now I had accurate plans, and knew all my mistakes. If I’d scratch built my ten gons, I might have stopped and said “good enough.” If I hadn’t thought that someone else might be interested in the gons, I might have stopped too. But now I knew I had an imprecise model. Worse, I had the ability to change that model.

Detail, Hart gondola door. Note how U bolts and angle iron were used to fabricate the hinges, and note the detail on the door latch that I never could see accurately in the photos.

I sat there for about 20 minutes just looking over the details. Ah, the straps hinging the side doors were actually angle iron, not steel strap. The trusses underneath the car were much deeper (3’) than I thought, and fabricated from larger iron angles. The metal aprons that could be flipped across car gaps only existed on the brake end of the car. I had the length and door spacing slightly wrong. I hadn’t quite understood the mechanism for opening the bottom dump doors.

If you look at the snippet from the drawing, you can see just how much detail is there. There are the revisions about where the handrails go on the car ends. You can see the “v” notch cut into the sides to hold the hinged-up doors. You can identify how metal rods wrapped around each post, then held the posts firm against the frame and truss. You can even see the metal plate joining the side frame and truss, and see the I beam going through the hopper area only joined to the inside of the frames - details I could sort of see in the photo, but now really understand.

Now, it's also worth noting that my original cars weren't that bad. The models I designed were eye-catching and reasonably accurate. The general proportions of the car were good. They're still worlds better than either of the two 1960's plastic or metal kits would have been. Many of the incorrect details I spotted were insanely minor - cases of replacing a metal plate and bolt with a pair of bolts-and-washers, or placing the removable ends just outside of the line of side posts. But I know there are inaccuracies.

So now I’m redoing the Hart gondola - stretching parts correctly, adding details that I hadn’t known about, and hopefully adding some parts of the mechanism. And once that’s done, it’s time to print, paint, and decal some accurate Hart gondolas

I’m still planning on dealing with the “rebuilt” Hart gondolas and the Battleships. I’m going up next week to see those plans. I suspect I’ll be spending a lot of time in front of the computer over the next couple weeks as I pore over some draftsman's really fine work. Stay tuned for more photos of 3d printed freight cars!

Snippets of drawings from Southern Pacific / Union Pacific C-1652 plan, used on SP’s class W-50-3. Last revision April 19, 1918. Original in California State Railroad Museum.